The Guide to Cryomilling and Refining Polymer Powders

Table of Contents

If you’re exploring polymer grinding for pharmaceutical applications, you’ve come across the idea of cryomilling or cryo grinding. Cryomilling empowers pharma companies to deliver more effective long-acting drug-delivery devices to patients who need them, and Particle Sciences is at the forefront of this innovative polymer grinding method.

This article explains the cryomilling process and highlights how this unique polymer milling technique can solve problems to create more effective drug-delivery devices. Read on to learn more.

What is Cryomilling

Cryomilling is the process of cooling or freezing a material, before or during milling, to reduce its particle size. It’s a mechanical process, typically using liquid nitrogen, performed under cryogenic conditions.

Cryomilling is essential, especially in drug-delivery devices. Most polymers in long-acting drug delivery require a cryomilling process to achieve uniform particle size reduction which promotes homogeneous drug and polymer blending.

Why is Cryomilling Important?

When producing drug delivery devices such as implantable drug delivery systems, precision and accuracy are paramount. Cryomilling is a critical formulation step to ensure dispersion of active pharmaceutical ingredients (i.e., APIs or drugs) within these polymeric devices.

The primary purpose of cryomilling in any industry is to reduce particle size. In this application, particle size reduction enhances the polymer’s flowability and processability within the specific manufacturing process.

Cryogrinding enhances the homogeneity of an API, especially highly potent APIs such as hormones, which are typically in very low concentrations. Because of the low drug concentration in a polymeric device, it’s difficult to disperse the API into the polymer evenly. By reducing the particle size of the polymer, we can improve homogeneity and, as a result, the safety and efficacy of the device.

How Does Cryomilling Work?

Traditional cryomilling typically involves complete submersion of material in a frozen environment, i.e., liquid nitrogen, then subjecting it to mechanical forces to break the material into smaller parts.

Traditional cryomilling typically involves complete submersion of material in a frozen environment, i.e., liquid nitrogen, then subjecting it to mechanical forces to break the material into smaller parts.

One of the significant drawbacks of traditional cryomilling is the size of equipment needed for complete submersion in liquid nitrogen and milling of the target material. Cryomilling equipment has historically scaled to the size of the target material amount being milled.

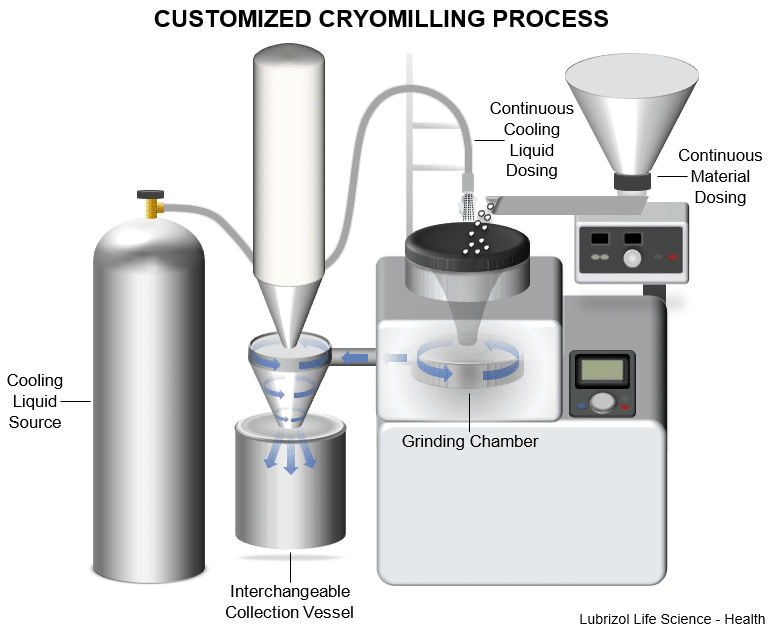

To address this, Particle Sciences developed a semi-continuous cryomilling process where the material to be milled is dosed into a milling chamber, maintained under cryogenic conditions, and subjected to mechanical impact to reduce its particle size. Centrifugal force is introduced to move the milled material away from the milling chamber and through selected sieve sizes, controlling its particle size distribution.

The Benefits of Cryomilling

The benefits of cryomilling vary according to unique industries and their applications. In the pharmaceutical industry, cryomilling offers these advantages:

Improves Homogeneity

A significant number of pharmaceutical drugs available today are highly potent. Due to their potency levels, small volumes of the drug are needed to achieve therapeutic effects. As a result, most drug devices contain very low concentrations of these drugs. The most challenging aspect of working with highly potent APIs is ensuring the drug is evenly dispersed throughout the device to safeguard or improve homogeneity.

Herein lies the greatest benefit of cryomilling: the ability to homogenize low-concentration APIs into a polymer.

Cryomilled polymers exhibit increased surface area compared to un-milled polymers, making it easier to homogeneously distribute a drug throughout the polymer.

Increases Production Safety

Cryomilling produces powdered polymers that give more flexibility when building a manufacturing process involving dosing the polymer and drug into equipment streams, i.e., a hot melt extrusion line. For example, when working with highly potent drugs or controlled substances, additional safety controls are required to prevent exposure to the operator or environment. In this case, dosing the powdered polymer and pharmaceutical drug blend can be performed in a closed system in one feed stream.

Enhances Flowability

Polymer comes to a CDMO or manufacturing facility in pellet form. When mixing polymer beads with drug powders, achieving the correct consistency is challenging. Cryomilling properly breaks down the polymer, enhancing mixture flowability that more easily feeds into the extruder to create the final product.

Ensures Temperature Control

Cryogenic milling provides temperature control to prevent the polymer’s degradation or decomposition when exposed to a mill’s high-energy environment.

Promotes Uniform Shattering

Cryomilling is a specialized technique that breaks down polymer particles efficiently, evenly, and effectively. And where you’re producing drug-delivery devices, this even breakdown and distribution is crucial.

There are alternative ways to mill polymers into particles, but the cryomilling approach is the most effective. Polymers are sensitive. If you try to mill them according to traditional milling techniques, they might melt or get rubbery and won’t break down. The cold temperatures ensure the particles shatter evenly.

Cryomilling Applications and Use Cases

Cryomilling can be used in creating nearly every type of drug device. In applications incorporating a drug into a polymer, cryomilling is a viable option. Common examples include:

- Intravaginal rings (IVRs)

- Subcutaneous implants

- Ocular implants

- Drug-eluting films and wafers

Any project developing a thermoplastic drug product with bioabsorbable or biostable polymers can benefit from cryomilling. Below are a few commonly used polymers used in cryomilling applications:

- Ethylene-Vinyl Acetate (EVA)

- Thermoplastic Polyurethane (TPU)

- Poly(lactic-co-glycolic Acid) (PLGA)

- Polycaprolactone (PCL)

The use cases for cryogenic milling are endless. And while cryomilling is the ideal solution for any drug device, the homogeneity provided becomes crucial as the devices get smaller.

Consider ocular implants for drug delivery. These devices are small, which means uniform blending is essential. Even a slight difference in drug concentrations within your polymer can significantly affect the device’s efficacy. Cryomilling plays a vital role in developing these types of implants that rely on homogenous mixtures and drug distribution.

Cryomilling FAQs

At Particle Sciences, we’re revolutionizing the landscape of cryomilling, expanding our clients’ understanding of what this process can accomplish. We field many questions regarding the cryomilling process, its benefits, and its applications. Below we address the most common inquiries we receive.

- What’s Your Cryomilling Batch Size?

We receive many questions related to batch sizes and processing speed. Most people think of cryomilling as a small-batch, inefficient process that’s difficult to scale up to produce enough material to make your device. Particle Sciences has developed our own cryomilling process that supports clinical batch sizes up to phase II clinical trial material.

Polymer micronization through cryomilling can be efficient, effective, and scalable. Particle Sciences’s unique cryogenic milling process allows us to deliver impressive batch sizes that meet your production timelines.

- Do We Need to Cryomill? Is it a Waste of Time and Resources?

Many view cryogenic milling as an extra step that wastes time, energy, and financial resources. But when creating drug delivery products, homogeneity is essential. Cryomilling is an effective way to achieve a uniform blend of polymer and drug to create an effective device.

- Does Particle Sciences Cryomill for Pharmaceutical Applications?

Our team fields many questions regarding the quality of our polymers and whether we can safely and responsibly cryomill for pharmaceutical use.

At Particle Sciences, we differentiate ourselves with our innovative approach to polymer milling. Our team has designed a mill for pharmaceutical GMP processing, bringing the proper quality support to cryomilling that allows for pharmaceutical applications.

- All pieces of equipment used in our cryomilling process are calibrated, qualified, and maintained under GMP.

- We carry all proper documentation to grind polymers that meet regulatory requirements.

- Contact parts of our mills are specifically chosen to ensure we’re not introducing impurities to the product. We use appropriate steels and materials of construct to prevent the introduction of foreign particles or elemental impurities into the blend.

The teams at Particle Sciences have experience incorporating cryomilling into hot melt extrusion processes to support development of long-acting drug devices. We’ve milled many different materials and batch sizes and have the experience to confidently deliver effective pharmaceutical prototypes to our clients.

- Can Particle Sciences Supply for 3D printing?

Polymer grinding is useful for individuals considering 3D printing as a polymer technology. If you want to 3D print for pharmaceutical applications via laser sintering or similar processes, Particle Sciences provides polymers that meet those specific needs and regulatory requirements.

How Particle Sciences CDMO Can Help

If you’re working on a long-acting drug delivery system or implant or want to work on one, cryomilling is a crucial component of your manufacturing. And as vital as it is to create a quality product, it’s just one component of your manufacturing process.

At Particle Sciences, we’re a one-stop shop. We handle everything from concept through cryomilling, extrusion, clinical production, product release, and stability testing. We problem-solve and deliver satisfying solutions, and it’s all done under one roof with one team. Our holistic approach streamlines your processes, resulting in a quality product with faster delivery from a team who knows your project inside and out.

We handle highly potent APIs and controlled substances and hold a DEA license. And because we’re polymer agnostic, we work with whichever polymer meets the needs of our customers’ projects. We help you achieve your drug release and device format targets and are able to leverage our vast experience to deliver unparalleled polymer expertise and robust drug product formulation.

Particle Sciences is a problem solver and solution provider for all your needs. Our team has the experience, expertise, and innovative equipment required to stay on top in this industry to deliver polymer solutions that work.

Click here to speak with our team and learn how Particle Sciences’s cryomilling solutions and other drug-eluting device capabilities can enhance your drug delivery technology.

Authors: Jite Okoh and Nick DiFranco